BATTENFELD-CINCINNATI

Extrusion line manufacturer intent on winning larger market share / CEO expects positive stimulus from "K"

Extrusion line manufacturer battenfeld-cincinnati (Bad Oeynhausen / Germany; www.battenfeld-cincinnati.de) is confident that its new organisational structure will afford it a higher share of the market in the near future. After the formation of three central divisions – Construction, Infrastructure and Packaging – the company will be more oriented to the end product, thereby securing its long-term success, CEO Jürgen Arnold told the audience at a recent press conference in Düsseldorf / Germany. The company restructured in April this year by merging the former sister companies Battenfeld and Cincinnati – see Plasteurope.com of 12.04.2010.

"Our restructuring comes at exactly the right time. The extrusion market is expanding, and the interest in innovative machine concepts has returned," said Arnold. Compared with the low of 2009, battenfeld-cincinnati has seen a significant rise in the number of incoming orders. From 2007 to 2009, Battenfeld and Cincinnati – like most machine manufacturers – suffered a sales slump of around 50%.

The newly restructured company expects the "K 2010" fair to provide it with a significant boost. At the event, held in Düsseldorf from October 27 to November 3, 2010, the Construction division will showcase a new parallel twin-screw extruder range for the extrusion of PVC. The four models with screw diameters of 78 - 135 mm and a processing unit of 34D cover a performance range for profile manufacture of 100 to 1,000 kg/h. This 25% performance increase over predecessor models apparently has been achieved by the longer processing unit and the use of the most powerful four-screw drive unit to date.

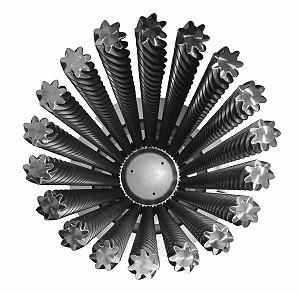

The Infrastructure division will present various concepts for shortening the cooling section in pipe extrusion to save energy costs, while the Packaging division will showcase a line of extruders for the direct extrusion of PET films – the three machine models cover the medium output range between 600 and 1,200 kg/h. A special feature of these processing machines, says battenfeld-cincinnati, is the combination of a normal single screw with a modified planetary-gear section, through which both virgin material and cleaned post-consumer flakes with an input moisture content of up to 1,000 ppm can be processed.

"Our restructuring comes at exactly the right time. The extrusion market is expanding, and the interest in innovative machine concepts has returned," said Arnold. Compared with the low of 2009, battenfeld-cincinnati has seen a significant rise in the number of incoming orders. From 2007 to 2009, Battenfeld and Cincinnati – like most machine manufacturers – suffered a sales slump of around 50%.

The newly restructured company expects the "K 2010" fair to provide it with a significant boost. At the event, held in Düsseldorf from October 27 to November 3, 2010, the Construction division will showcase a new parallel twin-screw extruder range for the extrusion of PVC. The four models with screw diameters of 78 - 135 mm and a processing unit of 34D cover a performance range for profile manufacture of 100 to 1,000 kg/h. This 25% performance increase over predecessor models apparently has been achieved by the longer processing unit and the use of the most powerful four-screw drive unit to date.

The Infrastructure division will present various concepts for shortening the cooling section in pipe extrusion to save energy costs, while the Packaging division will showcase a line of extruders for the direct extrusion of PET films – the three machine models cover the medium output range between 600 and 1,200 kg/h. A special feature of these processing machines, says battenfeld-cincinnati, is the combination of a normal single screw with a modified planetary-gear section, through which both virgin material and cleaned post-consumer flakes with an input moisture content of up to 1,000 ppm can be processed.

The modified planetary-gear section for PET outgassing (Photo: battenfeld-cincinnati) |

05.07.2010 Plasteurope.com [216619]

Published on 05.07.2010

German version of this article...

German version of this article...