ARCOPLASTICA

PET thermoforming specialist to process household waste / Installation of cleaning and granulating plant

By Plasteurope.com staff

Italian thermoforming company Arcoplastica (Andezeno; www.arcoplastica.com/en) said it is taking recyclate processing a step further and will in future also work with PET waste from household collections. While Arcoplastica previously concentrated predominantly on recycling its own production scrap, CEO Marco Torta said the company now plans to pursue tray-to-tray recovery to a greater extent.

Italian thermoforming company Arcoplastica (Andezeno; www.arcoplastica.com/en) said it is taking recyclate processing a step further and will in future also work with PET waste from household collections. While Arcoplastica previously concentrated predominantly on recycling its own production scrap, CEO Marco Torta said the company now plans to pursue tray-to-tray recovery to a greater extent.

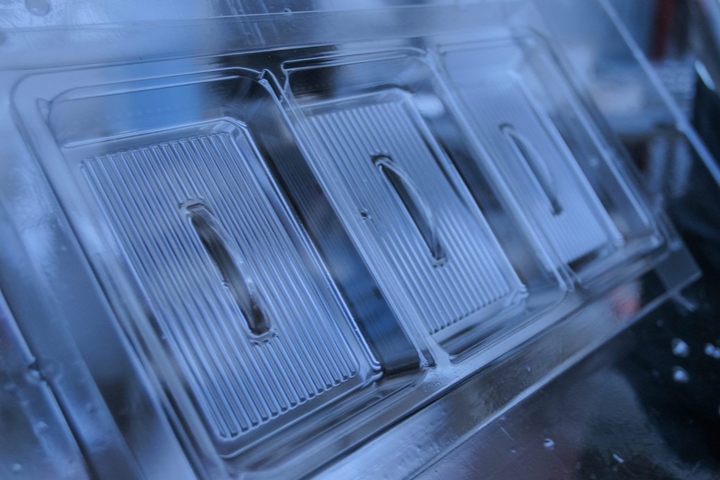

Arcoplastica’s speciality: thermoformed PET trays for food packaging, also available in large format (Photo: PIE) |

Arcoplastica has been continuously investing in the use of recyclate since 2020. Initially, the company installed three grinding lines, followed two years later by a PURe1500 line from compatriot blown film plant manufacturer Bandera (Venegono; www.luigibandera.com) for the cleaning and granulation of PET regrind for food-contact applications.

Related: Food and drink packaging demand in Europe to rise 1.65% annually to 2028

The aim is to produce PET thermoformed film with a recyclate content of 100%. In response to a Plasteurope.com query, Torta puts the quantity of reclaimed materials used at around 4,000 t/y, with 1,800 t/y of PET flakes being purchased by Arcoplastica to meet this volume.

At its headquarters in Andezeno near Turin, the family-owned firm operates three PET and polypropylene extrusion lines with a combined capacity of 13,000 t/y, in addition to 24 thermoforming lines that process a large majority of these films.

Apart from the main material PET (7,900 t/y), the company’s portfolio of cast film with up to seven layers also comprises PP film (3,720 t/y) – in part with an EVOH oxygen barrier – and also film made from the biopolymer PLA. It also offers rigid films from engineering polymers such as ABS, PMMA, and polycarbonate, though the volumes are comparatively minor at 380 t/y.

Most recently, the company has also been concentrating on the development of PET monomaterial films instead of multi-layer variants. Here, Arcoplastica said it has opted for a new PET type for packaging under a protective atmosphere. The aim is to achieve an oxygen barrier by means of additives – a barrier which, according to CEO Torta, is equivalent to that of a multi-layer film that is more difficult to recycle.

— Translated by Jon Relton

19.06.2024 Plasteurope.com [255589-0]

Published on 19.06.2024

German version of this article...

German version of this article...