RESEARCH

Self-healing resin with range of qualities said to biodegrade in seawater / Material contains vitrimer, polyrotaxane

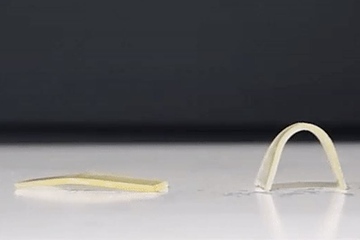

Vitrimer plastic with polyrotaxane (l.) flattens again when heated to 120°C (Photo: University of Tokyo/Shota Ando) |

Scientists at the University of Tokyo (https://www.u-tokyo.ac.jp/en/) in Japan said they have created a polymer that has a wide range of welcome properties, including the ability to feed ocean bacteria.

They said their VPR material is made by adding polyrotaxane (PR), a type of interlocked molecule consisting of strings and rings, to an epoxy resin vitrimer, a class of plastics derived from thermosetting polymers, which are solid and strong at lower temperatures like a thermoset but can also be reshaped multiple times at higher temperatures like a thermoplastic.

The researchers describe VPR as hard but stretchable, unlike conventional epoxy resins, so it can strongly bond materials of different hardness and elongation. As opposed to most vitrimers, VPR can hold its form and has strong internal chemical bonds at low temperatures, but at temperatures above 150°C those bonds recombine, and the material can be reformed into different shapes so it can be healed with heat and remembers its shape.

VPR is also biodegradable, according to the researchers, who said the material could promote a circular economy as an alternative that can be reused and recycled more easily, or which are made from environmentally friendly sources.

They said their VPR material is made by adding polyrotaxane (PR), a type of interlocked molecule consisting of strings and rings, to an epoxy resin vitrimer, a class of plastics derived from thermosetting polymers, which are solid and strong at lower temperatures like a thermoset but can also be reshaped multiple times at higher temperatures like a thermoplastic.

The researchers describe VPR as hard but stretchable, unlike conventional epoxy resins, so it can strongly bond materials of different hardness and elongation. As opposed to most vitrimers, VPR can hold its form and has strong internal chemical bonds at low temperatures, but at temperatures above 150°C those bonds recombine, and the material can be reformed into different shapes so it can be healed with heat and remembers its shape.

VPR is also biodegradable, according to the researchers, who said the material could promote a circular economy as an alternative that can be reused and recycled more easily, or which are made from environmentally friendly sources.

Researcher touts chemical recyclability

VPR is over five times as resistant to breaking as a typical epoxy resin vitrimer, said professor Shota Ando, a project assistant. “(VPR) also repairs itself fifteen times as fast, can recover its original memorised shape twice as fast, and can be chemically recycled ten times as fast as the typical vitrimer,” Ando said.

In a study, VPR showed improved toughness, meaning that more complex shapes could be created and retained, even at low temperatures.

Submerging VPR in seawater for 30 days results in 25% degradation, with the polyrotaxane breaking down into a food source for marine life, researchers said. In comparison, vitrimer without PR did not undergo any apparent biodegradation, the researchers said.

Disposal or recycling was also said to be easier for VPR than for vitrimers without polyrotaxane. “Although this resin is insoluble in various solvents at room temperature, it can be easily broken down to the raw material level when immersed in a specific solvent and heated,” Ando said.

In a study, VPR showed improved toughness, meaning that more complex shapes could be created and retained, even at low temperatures.

Submerging VPR in seawater for 30 days results in 25% degradation, with the polyrotaxane breaking down into a food source for marine life, researchers said. In comparison, vitrimer without PR did not undergo any apparent biodegradation, the researchers said.

Disposal or recycling was also said to be easier for VPR than for vitrimers without polyrotaxane. “Although this resin is insoluble in various solvents at room temperature, it can be easily broken down to the raw material level when immersed in a specific solvent and heated,” Ando said.

14.11.2023 Plasteurope.com [253976-0]

Published on 14.11.2023