AEROSPACE

Aimplas and partners research development of novel polymers under space conditions

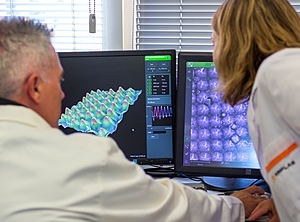

Aimplas plans to develop new materials under the microgravity and vacuum conditions of space (Photo: Aimplas) |

Spanish plastics technology centre Aimplas (Valencia; www.aimplas.net) is undertaking its first aerospace venture as part of a six-member consortium with the European Space Agency (ESA, Paris; www.esa.int) to develop new materials under the microgravity and vacuum conditions of space.

Aimplas said the project opens a new research area on advanced plastic materials whose quality and performance are much better than materials developed in regular Earth conditions.

The Advanced Materials Accelerator was created as an initiative of the ESA’s Business in Space Growth Network (BSGN) programme and focuses on five areas of advanced materials technology: novel polymers and fibres; superalloys and hybrid materials; nanomaterials; functional coatings and thin film systems; and advanced ceramics.

“Working under microgravity and vacuum conditions opens a world of possibilities for creating revolutionary next-generation materials. Identifying attractive projects for companies interested in exploring this pathway and supporting their developments in collaboration with the industry is a major challenge and a great opportunity,”said Carolina Losada, principal investigator for the project at Aimplas.

Related: Aimplas'lightcar project to slash weight of e-vehicle batteries by half

The first phase of the project, led by UK consortium partner Satellite Applications Catapult (Oxford; https://sa.catapult.org.uk) will focus on generating interest and demand in the growing in-orbit servicing and manufacturing industry so that advanced manufacturing companies can explore the possibilities that space has to offer and get involved in the programme. This phase has a budget of EUR 411,000, 67% of which is funded by ESA and 33% through an in-kind contribution from the project partners.

Future phases will focus on upscaling the opportunities identified in phase one in each area, including in-orbit demonstrations and the delivery of prototype products. The Programme aims to guarantee at least EUR 1 mn in funding for future phases from ESA, up to a maximum of EUR 5 mn.

The other four partners of the consortium are

Aimplas said the project opens a new research area on advanced plastic materials whose quality and performance are much better than materials developed in regular Earth conditions.

The Advanced Materials Accelerator was created as an initiative of the ESA’s Business in Space Growth Network (BSGN) programme and focuses on five areas of advanced materials technology: novel polymers and fibres; superalloys and hybrid materials; nanomaterials; functional coatings and thin film systems; and advanced ceramics.

“Working under microgravity and vacuum conditions opens a world of possibilities for creating revolutionary next-generation materials. Identifying attractive projects for companies interested in exploring this pathway and supporting their developments in collaboration with the industry is a major challenge and a great opportunity,”said Carolina Losada, principal investigator for the project at Aimplas.

Related: Aimplas'lightcar project to slash weight of e-vehicle batteries by half

The first phase of the project, led by UK consortium partner Satellite Applications Catapult (Oxford; https://sa.catapult.org.uk) will focus on generating interest and demand in the growing in-orbit servicing and manufacturing industry so that advanced manufacturing companies can explore the possibilities that space has to offer and get involved in the programme. This phase has a budget of EUR 411,000, 67% of which is funded by ESA and 33% through an in-kind contribution from the project partners.

Future phases will focus on upscaling the opportunities identified in phase one in each area, including in-orbit demonstrations and the delivery of prototype products. The Programme aims to guarantee at least EUR 1 mn in funding for future phases from ESA, up to a maximum of EUR 5 mn.

The other four partners of the consortium are

- Centre for Process Innovation (CPI, Wilton, UK; www.uk-cpi.com)

- Innovate UK’s Knowledge Transfer Network (Swindon, UK; www.ktn-uk.org)

- German aerospace centre DLR (Cologne, Germany; www.dlr.de/wf/en)

- National Composites Centre (NCC, Bristol, UK; www.nccuk.com)

08.07.2022 Plasteurope.com [250690-0]

Published on 08.07.2022