TEKNOR APEX

Development of PLA compounds for 3D printing / Heat resistance and impact strength combined in same grade

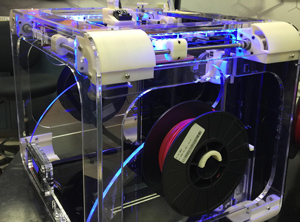

PLA for 3D printing (Photo: Teknor Apex) |

The bioplastics division of US custom compounder Teknor Apex (Pawtucket, Rhode Island; www.teknorapex.com) has launched a new series of PLA compounds in the "Terraloy" range. The "Terraloy 3D-40040" compounds have been formulated for use in 3D printing.

The products have improved heat deflection temperatures and impact strength compared with standard PLA and offer tight tolerance control after annealing, the company said. Because of its heat resistance, filaments made from the compounds can be dried easily in an oven before processing which, according to Teknor Apex, is an important advantage because of the hygroscopic nature of standard PLA.

Edwin Tam, manager of new strategic initiatives at Teknor Apex, said: “Our new Terraloy compound combines two technologies in which today’s plastics industry has an intense interest – 3D printing and bioplastics. Teknor Apex has developed formulation and compounding methods that enhance the toughness and heat-resistance of PLA by eliminating certain property trade-offs normally encountered with standard grades of this resin.”

Teknor Apex said it had overcome an inverse relationship in standard PLA between heat distortion temperature (HDT) and Izod impact strength. The new products have up to two times the HDT and more than four times the impact strength of standard PLA resins and combine both properties in the same grade.

The products have improved heat deflection temperatures and impact strength compared with standard PLA and offer tight tolerance control after annealing, the company said. Because of its heat resistance, filaments made from the compounds can be dried easily in an oven before processing which, according to Teknor Apex, is an important advantage because of the hygroscopic nature of standard PLA.

Edwin Tam, manager of new strategic initiatives at Teknor Apex, said: “Our new Terraloy compound combines two technologies in which today’s plastics industry has an intense interest – 3D printing and bioplastics. Teknor Apex has developed formulation and compounding methods that enhance the toughness and heat-resistance of PLA by eliminating certain property trade-offs normally encountered with standard grades of this resin.”

Teknor Apex said it had overcome an inverse relationship in standard PLA between heat distortion temperature (HDT) and Izod impact strength. The new products have up to two times the HDT and more than four times the impact strength of standard PLA resins and combine both properties in the same grade.

13.04.2015 Plasteurope.com [230919-0]

Published on 13.04.2015

German version of this article...

German version of this article...