TEKNOR APEX

New blend developed for faster composting

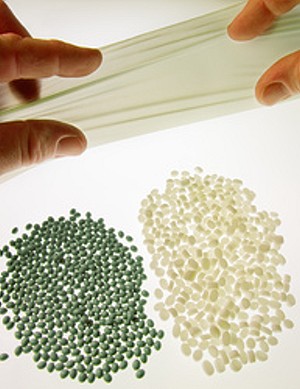

New blend enables thicker sheet to meet composting requirements (Photo: Teknor) |

Teknor Apex (Pawtucket, Rhode Island / USA; www.teknorapex.com) says its new blend of thermoplastic starch (TPS) and biodegradable copolyester (PBAT) degrades more rapidly than the copolyester alone, broadening applications for film, sheet and moulded parts intended for composting.

The “Terraloy” 20000 compounds have a TPS content of up to 40%, and have passed the ASTM D6400 test for plastics intended for composting in aerobic facilities. They can be used to replace polyolefins and PS in applications including carrier bags, can liners, trays and plates, cutlery and flower pots, Teknor Apex says.

The development speeds up the biodegradation of films and enables thicker sheet and moulded parts to meet compostability requirements, the company explains.

In the new blend, the TPS is melt-mixed with the copolyester so the key properties of the copolyester are retained, says Edwin Tam, manager of strategic initiatives. “The process employed by Teknor Apex for intimately dispersing TPS within the host polymer makes it possible for plastics processors to do more with biodegradable copolyester,” he adds.

The “Terraloy” 20000 compounds have a TPS content of up to 40%, and have passed the ASTM D6400 test for plastics intended for composting in aerobic facilities. They can be used to replace polyolefins and PS in applications including carrier bags, can liners, trays and plates, cutlery and flower pots, Teknor Apex says.

The development speeds up the biodegradation of films and enables thicker sheet and moulded parts to meet compostability requirements, the company explains.

In the new blend, the TPS is melt-mixed with the copolyester so the key properties of the copolyester are retained, says Edwin Tam, manager of strategic initiatives. “The process employed by Teknor Apex for intimately dispersing TPS within the host polymer makes it possible for plastics processors to do more with biodegradable copolyester,” he adds.

05.05.2010 Plasteurope.com [216125]

Published on 05.05.2010

German version of this article...

German version of this article...