SABIC

Launch of conductive polymer range / PPE for inline paintable automotive exteriors

— By Plasteurope.com correspondent —

Saudi Arabian petrochemicals giant Sabic (Riyadh; www.sabic.com) has introduced a family of conductive polymers suitable as a replacement for PA-based polymers used in inline paintable automotive exteriors.

Saudi Arabian petrochemicals giant Sabic (Riyadh; www.sabic.com) has introduced a family of conductive polymers suitable as a replacement for PA-based polymers used in inline paintable automotive exteriors.

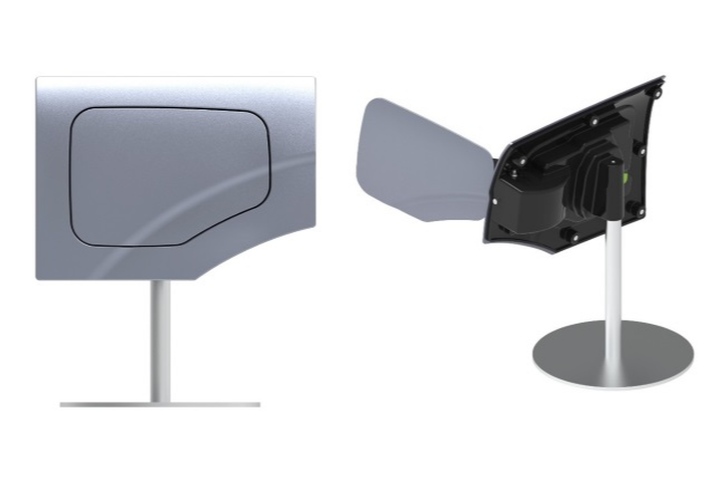

Sabic has launched conductive polymers for inline paintable exterior car parts (Photo: Sabic) |

Its Noryl GTX LMX310 poylmer, the first in the new product line, is an unfilled, proprietary polyphenylene ether (PPE) blend that offers high heat resistance required for inline painting of larger, asymmetrically shaped automotive parts such as service flaps for electric vehicles, the company said. The new material also features dimensional stability and very low moisture absorption.

Related: Car industry shoulders extra costs for next-gen materials, components

Testing performed by Sabic demonstrated that the PPE grade absorbs 85% less moisture at equilibrium than PA-based polymers. This reduces the risk of warpage by up to 90%, the company said.

According to Sabic, the material helps carmakers ensure Class A colour matching while reducing both costs and carbon emissions.

Sabic said it leveraged the expertise under its Bluehero electrification initiative to develop the material. The initiative’s specialisation is in enabling the car sector to accelerate the transition to electric vehicles.

10.03.2025 Plasteurope.com [257462-0]

Published on 10.03.2025