SABIC INNOVATIVE PLASTICS

Custom-colourable compound for LDS processing

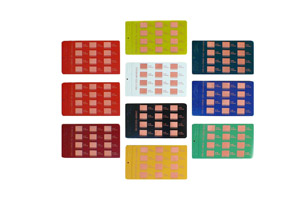

“LNP Thermocomp” adds colour to LDS components (Photo: Sabic Innovative Plastics) |

Sabic Innovative Plastics (Bergen op Zoom / The Netherlands; www.sabic-ip.com) has introduced a custom-colourable thermoplastic compound for laser direct structuring (LDS) that can save space and reduce the weight of mobile devices. “LNP Thermocomp” can be processed using LDS, in which lasers scribe the circuit layout of a component on to a moulded plastic part. The layout is then plated, with the resulting circuit pathway copying the laser pattern, integrating electronic and mechanical functionality into a single module, such as mobile phone and notebook antennas.

Previously, only black plastic materials were available and LDS components were typically used in a device’s interior. Cathleen Hess, global product marketing director, LNP, Sabic IP, said: “LDS is a powerful technology for achieving greater miniaturisation in mobile phones, notebooks and tablets, but until now, it had aesthetic limitations. By developing a colourable material for LDS applications, Innovative Plastics has improved upon an already successful technology.”

Previously, only black plastic materials were available and LDS components were typically used in a device’s interior. Cathleen Hess, global product marketing director, LNP, Sabic IP, said: “LDS is a powerful technology for achieving greater miniaturisation in mobile phones, notebooks and tablets, but until now, it had aesthetic limitations. By developing a colourable material for LDS applications, Innovative Plastics has improved upon an already successful technology.”

15.06.2011 Plasteurope.com [219608-0]

Published on 15.06.2011

German version of this article...

German version of this article...