NATUREWORKS

Bioresin developed for injection moulding of semi-durables

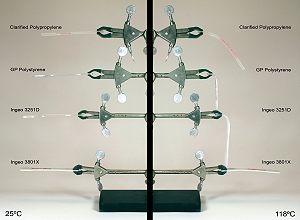

The new Ingeo 3801X performs well in conditions of high temperature, during impact and cycle times (Photo: NatureWorks) |

NatureWorks (Minnetonka, Minnesota / USA; www.natureworksllc.com) has introduced a new formulation of its “Ingeo” PLA bioresin targeted primarily at injection moulding of semi-durable consumer products. The company said the product, branded Ingeo 3801X, combines a high percentage PLA base resin with a tailored additive package designed to achieve the high heat, impact and cycle time performance requirements of semi-durable products such as cosmetics, consumer electronics, toys and office accessories.

The compounded resin technology enables the production of injection moulded parts with thermal dimensional stability of up to 120 °C, notched Izod impact strength greater than two foot-pounds per inch and modulus of approximately 450,000 psi, NatureWorks said. The injection moulding cycle time compares to that of styrenic resins, it added.

The compounded resin technology enables the production of injection moulded parts with thermal dimensional stability of up to 120 °C, notched Izod impact strength greater than two foot-pounds per inch and modulus of approximately 450,000 psi, NatureWorks said. The injection moulding cycle time compares to that of styrenic resins, it added.

22.01.2010 Plasteurope.com [215292]

Published on 22.01.2010

German version of this article...

German version of this article...