KRONES

Monobloc unit produces and fills up to 81,000 small-cavity PET containers hourly / First installations in the US

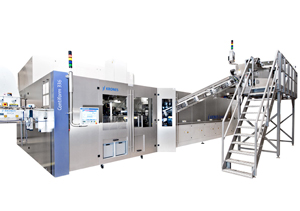

Up to 81,000 small-cavity PET containers can be produced, labelled and filled every hour with the “Contiform” 3 series (Photo: Krones) |

The latest generation of the “Contiform” 3 series from PET stretch blow moulding specialist Krones (Neutraubling / Germany; www.krones.de) is claimed to offer the highest output available, at 81,000 PET containers produced per hour, followed by labelling and filling in a monobloc unit. The high-speed stretch blow moulding machine produces containers up to 0.75 l and is fitted with a newly developed blow moulding station which operates without lubrication. Krones said the machines are low maintenance and are simple to operate with low standstill times.

The company also said it already has the same level of output installed and running in a number of beverage plants. Four “Contiform” 3 SC (small-cavity) machines have been installed at a bottler in the US and two additional machines have been ordered by another bottler. All six high-speed stretch blow moulding machines produced have been integrated into the Krones “ErgoBloc” L wet-end monobloc.

The company also said it already has the same level of output installed and running in a number of beverage plants. Four “Contiform” 3 SC (small-cavity) machines have been installed at a bottler in the US and two additional machines have been ordered by another bottler. All six high-speed stretch blow moulding machines produced have been integrated into the Krones “ErgoBloc” L wet-end monobloc.

13.11.2013 Plasteurope.com [226747-0]

Published on 13.11.2013

German version of this article...

German version of this article...