JOHNS MANVILLE

Glass fibre technology for structural thermoplastic composites / Improved glass-matrix bonding claimed

US glass fibre products manufacturer Johns Manville (JM, Denver, Colorado; www.jm.com) has introduced an engineered reactive glass fibre, ”StarRov”, for improved performance in structural thermoplastic composites.

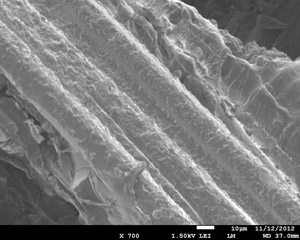

"StarRov" glass fibre improves not only strength but also dimensional stability (Photo: Johns Manville) |

The technology has allowed the development of products including “StarRov” RXN886, which is ready for testing for use in the in-mould caprolactam polymerisation process. The material maximizes glass-matrix bonding, resulting in improvements in strength, multi-axial impact, aging performance and dimensional stability of PA 6-based structural composites, the company said. The material is now available for testing by customers in a variety of processes, including thermoplastic RTM, RIM, pultrusion and filament winding.

Johns Manville has additionally developed two chopped strand materials, “ThermoFlow” 674 and 601, for glass reinforcement in PA and PBT/PET engineered thermoplastics respectively. The strands provide material engineers flexibility to enhance thermoplastic performance when plastic materials and articles are intended to come into contact with food.

Enno Henze, JM’s vice president and general manager for engineered products Europe/Asia, said: “Our 'ThermoFlow' product line enables our customers to engineer reinforced polymer compounds with outstanding mechanical performance and chemical resistance whether they are based on polyamides, polyesters, polypropylene or specialty polymers. With our recent expansion of the Trnava / Slovakia facility [see Plasteurope.com of 20.02.2012], we are in a great position to support the growth agenda of our customers."

Johns Manville has additionally developed two chopped strand materials, “ThermoFlow” 674 and 601, for glass reinforcement in PA and PBT/PET engineered thermoplastics respectively. The strands provide material engineers flexibility to enhance thermoplastic performance when plastic materials and articles are intended to come into contact with food.

Enno Henze, JM’s vice president and general manager for engineered products Europe/Asia, said: “Our 'ThermoFlow' product line enables our customers to engineer reinforced polymer compounds with outstanding mechanical performance and chemical resistance whether they are based on polyamides, polyesters, polypropylene or specialty polymers. With our recent expansion of the Trnava / Slovakia facility [see Plasteurope.com of 20.02.2012], we are in a great position to support the growth agenda of our customers."

26.03.2013 Plasteurope.com [224911-0]

Published on 26.03.2013

German version of this article...

German version of this article...