EXTRUSION DIES INDUSTRIES

New "active microlayer" technology said to produce food packaging oxygen and moisture barrier "beyond current testing procedures" / Incorporates more than a hundred microlayers

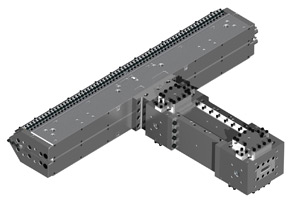

EDI’s layer multiplier die system employs two feedblocks, with a total of four extruders, whose output is combined through a number of processes to achieve multiple repetitions of the layer structure before the film or sheet is extruded (Photo: EDI) |

US die manufacturing specialist Extrusion Dies Industries (EDI, Chippewa Falls, Wisconsin; www.extrusiondies.com) has developed a technology that it claims will extend oxygen and moisture barrier properties in food packaging "beyond the limit of standard test procedures". The company’s "active microlayer" technology combines active packaging and microlayer extrusion, producing film and sheet in which layer multiplication is applied to both the barrier polymer and active components such as oxygen absorbers or desiccants.

The company said earlier research had shown that by dividing and recombining the barrier layer to create many micro-barrier layers, it is possible to significantly increase the shelf life of retort and hot-fill containers, stand-up pouches and vacuum skin packaging. Its researchers have taken a further step by incorporating active components in layers outside the barrier core, then subjecting those components to layer multiplication as well. Layer multiplication technology is claimed to produce film or sheet that is no thicker and contains no more polymer than a conventional coextrusion, but can incorporate over a hundred microlayers, instead of the usual three to eleven layers of standard thickness.

Gary Oliver, EDI’s vice president of technology, claims that the combined protection of food contents by multiple barrier and active layers appears to be greater than standard tests for oxygen and moisture ingress are designed to measure. "After encountering numerous active-component layers, oxygen is largely absorbed before it even reaches the barrier layer, as is moisture before it gets a chance to degrade barrier material such as EVOH," he said.

Extrusion Dies was acquired by Bertram Capital at the end of 2010. The private equity holding at the beginning of April appointed Gary Edwards its new CEO. Aside from its main plant, EDI also operates sites in Reichshof-Wehnrath / Germany as well as Shanghai / China.

The company said earlier research had shown that by dividing and recombining the barrier layer to create many micro-barrier layers, it is possible to significantly increase the shelf life of retort and hot-fill containers, stand-up pouches and vacuum skin packaging. Its researchers have taken a further step by incorporating active components in layers outside the barrier core, then subjecting those components to layer multiplication as well. Layer multiplication technology is claimed to produce film or sheet that is no thicker and contains no more polymer than a conventional coextrusion, but can incorporate over a hundred microlayers, instead of the usual three to eleven layers of standard thickness.

Gary Oliver, EDI’s vice president of technology, claims that the combined protection of food contents by multiple barrier and active layers appears to be greater than standard tests for oxygen and moisture ingress are designed to measure. "After encountering numerous active-component layers, oxygen is largely absorbed before it even reaches the barrier layer, as is moisture before it gets a chance to degrade barrier material such as EVOH," he said.

Extrusion Dies was acquired by Bertram Capital at the end of 2010. The private equity holding at the beginning of April appointed Gary Edwards its new CEO. Aside from its main plant, EDI also operates sites in Reichshof-Wehnrath / Germany as well as Shanghai / China.

02.05.2011 Plasteurope.com [219262-0]

Published on 02.05.2011

German version of this article...

German version of this article...