EVONIK

Pilot project with Remondis reclaims PU mattress foam / Testing commences in Germany

To support its efforts toward closing the material cycle for polyurethane, German chemical producer Evonik (Essen; www.evonik.com) has enlisted the aid of compatriot waste management firm Remondis (Lünen; www.remondis.de) in recovering end-of-life mattress foam.

At a pilot plant in Hanau, Germany, Evonik is currently testing a hydrolysis process to retrieve the main components of the foam to be chemically recycled into high-quality building blocks for new mattresses. In a subsequent step, the technology is to be tested in a larger demonstration plant.

At a pilot plant in Hanau, Germany, Evonik is currently testing a hydrolysis process to retrieve the main components of the foam to be chemically recycled into high-quality building blocks for new mattresses. In a subsequent step, the technology is to be tested in a larger demonstration plant.

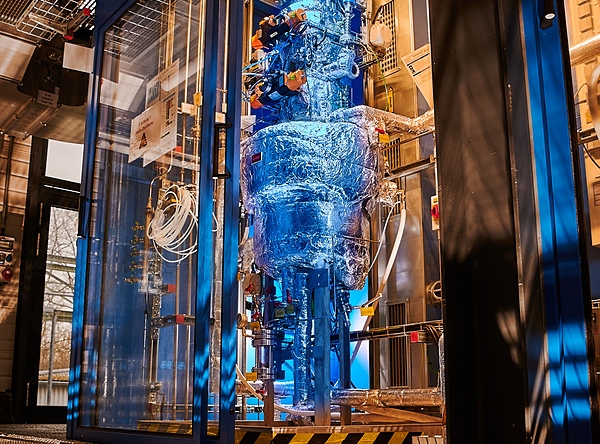

Evonik’s pilot plant in Hanau for PU mattress recycling (Photo: Evonik) |

The collaboration with the waste group builds on an earlier pact with flexible foam producer Vita Group (Luxembourg; www.thevitagroup.com) begun in 2021, in which Evonik says it established that its process can recover raw materials of “significantly higher quality” compared with existing recycling technologies.

In the current project, which will initially be concentrated in the German state of North Rhine-Westphalia but could be expanded internationally, Remondis will contribute its expertise in sorting PU flexible foam from waste streams and feeding it into the cycle in constant quality so that it can be used to feed Evonik’s process.

At the scale tested to date, the chemical producer says the process has been shown to lower the carbon footprint of mattress production versus that of fossil fuel-based technologies, a result it hopes the demonstration plant will prove on a larger scale.

Related: Mattress recycling makes progress

“By working together with Remondis, we can evolve from the current linear value chains to functioning circular loops,” said Patrick Glöckner, head of Evonik’s global circular economy programme.

In Evonik’s estimate, more than 250,000 t of PU foam from old mattresses is incinerated or landfilled in Europe annually, so returning more of this to the raw material cycle value chain should improve circularity.

According to Remondis managing director Jürgen Ephan, the waste company collects more than 30 mn t/y of recyclable materials, which it processes and makes available to industry as raw material, with the volume continuing to increase.

Other European cross-border projects developing foam recycling processes for mattresses include work between Germany’s Covestro and Belgium’s Recticel (more here), and the collaboration between Austria’s Neveon and BASF.

20.09.2023 Plasteurope.com [253621-0]

Published on 20.09.2023

German version of this article...

German version of this article...