ERZE

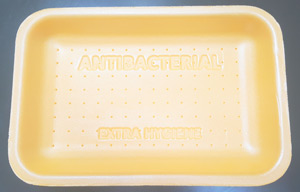

Collaboration with Parx Plastics to develop antimicrobial foam packaging / Technology achieves over 90% reduction in bacteria through change to surface properties

The two companies are now looking into economical ways of incorporating the technology (Photo: Parx Plastics) |

Turkey’s largest foam packaging producer Erze Ambalaj (Kemalpasa Izmir; www.erze.com) is working with biochemistry developer Parx Plastics (Rotterdam / The Netherlands; www.parxplastics.com) on the development of antimicrobial packaging.

The technology is derived from bio-mimicry, which emulates nature’s patterns and solutions, is free from biocides and significantly reduces the growth of Salmonella, Listeria, E.Coli and Staphylococcus Aureus on packaging. The two companies have researched ways to incorporate the technology into expanded foam packaging in an economical way to make it available across Erze’s product range.

The antibacterial performance of the resulting foam packaging, measured according to ISO 22196 by the independent University of Ferrara (www.unife.it) in Italy, is 92.5% against Listeria, 96% against Salmonella and up to 96.5% against Staphylococcus Aureus. The companies said this results in 93-97% less bacteria on the surface of the packaging material after 24 hours compared to normal packaging of the same kind.

The Parx technology uses one of the most abundant trace elements in the human body to achieve a change in the packaging material’s mechanical/physical property characteristics. The technology does not use biocides and has an impact on bacterial growth through changed material surface properties. The trace element used is compliant with European regulations for plastics that come in contact with food and does not migrate from the packaging.

The technology is derived from bio-mimicry, which emulates nature’s patterns and solutions, is free from biocides and significantly reduces the growth of Salmonella, Listeria, E.Coli and Staphylococcus Aureus on packaging. The two companies have researched ways to incorporate the technology into expanded foam packaging in an economical way to make it available across Erze’s product range.

The antibacterial performance of the resulting foam packaging, measured according to ISO 22196 by the independent University of Ferrara (www.unife.it) in Italy, is 92.5% against Listeria, 96% against Salmonella and up to 96.5% against Staphylococcus Aureus. The companies said this results in 93-97% less bacteria on the surface of the packaging material after 24 hours compared to normal packaging of the same kind.

The Parx technology uses one of the most abundant trace elements in the human body to achieve a change in the packaging material’s mechanical/physical property characteristics. The technology does not use biocides and has an impact on bacterial growth through changed material surface properties. The trace element used is compliant with European regulations for plastics that come in contact with food and does not migrate from the packaging.

07.12.2015 Plasteurope.com [232806-0]

Published on 07.12.2015