DOMO

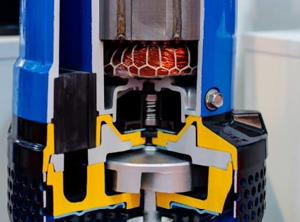

PPS-based material designed to replace sintered carbon in submersible pumps

The material is said to offer better performance than sintered carbon (Photo: Domo) |

Polyamide materials specialist Domo Chemicals (Leuna / Germany; www.domochemicals.com) has announced the expansion of its “Thermec” range of enhanced polymers with the introduction of a material designed to replace sintered carbon in submersible pump thrust bearing applications. “Thermec S” is a glass- and mineral-filled lubricated polyphenylene sulfide (PPS) based material said to offer high abrasion and wear resistance properties to improve tool life.

Along with cost-effectiveness, it also offers better performance than sintered carbon, the company said, noting that the material is suitable for both injection moulding and extrusion applications.

Submersible pumps are predominantly used for agricultural irrigation purposes and placed several meters below ground for water extraction, Domo explained. Thrust bearings in the units undergo continuous rotation and rub against sand, mud, and the metal surface of the bearing housing, causing a rise in temperature during operations, it noted. High subterranean pressure means the parts are subjected to high temperature and pressure conditions.

Along with cost-effectiveness, it also offers better performance than sintered carbon, the company said, noting that the material is suitable for both injection moulding and extrusion applications.

Submersible pumps are predominantly used for agricultural irrigation purposes and placed several meters below ground for water extraction, Domo explained. Thrust bearings in the units undergo continuous rotation and rub against sand, mud, and the metal surface of the bearing housing, causing a rise in temperature during operations, it noted. High subterranean pressure means the parts are subjected to high temperature and pressure conditions.

08.10.2020 Plasteurope.com [246059-0]

Published on 08.10.2020