CANON

Japanese group launches equipment portfolio that uses Raman spectroscopy technology / Detection of hard-to-spot black plastics

By Plasteurope.com correspondent

Nearly a year after revealing it had developed a process for sorting plastic pieces destined for recycling based on material, using “tracking type” Raman spectroscopy technology, Japanese technology giant Canon (www.global.canon) has now begun to sell the sorting equipment involved in the process.

Nearly a year after revealing it had developed a process for sorting plastic pieces destined for recycling based on material, using “tracking type” Raman spectroscopy technology, Japanese technology giant Canon (www.global.canon) has now begun to sell the sorting equipment involved in the process.

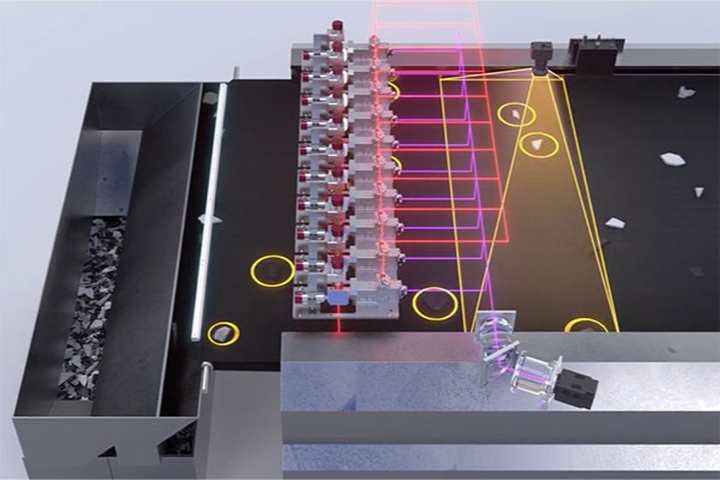

Internal view of the sorting equipment (Photo: Canon) |

Canon said black plastics, often used in home electronics or automobile upholstery, did not transmit or reflect visible light, making it difficult to identify and sort such materials using conventional near-infrared spectroscopy.

The firm said its TR Series equipment speeds up the sorting process, as it “applies Raman spectroscopy technology to moving objects with a tracking mechanism to collectively detect the material types of plastic fragments with high accuracy, even when black plastic pieces are mixed with other colours, which has been conventionally challenging”.

Canon added that its new product maintains a conveyor speed of 1.5 m per second and can sort up to 1 t of plastics per hour, while it can also be customised according to a customer’s throughput and installation space “by changing the module which tracks and measures the plastic pieces or the combination of conveyor belts”.

13.06.2024 Plasteurope.com [255544-0]

Published on 13.06.2024