BASF

Refinements applied to three styrene copolymer ranges / Attention to surface finish and durability

Styrenics product developers at BASF (Ludwigshafen / Germany; www.basf.com) have refined the company’s “Terblend” N, “Terluran” HH and “Luran” S speciality styrene copolymers to give them even more attractive surfaces, higher temperature or UV resistance, and improved flow properties. These and other advances will be showcased by the company at “K 2010” (www.k-online.de) in Düsseldorf / Germany in late October – see Plasteurope.com of 22.06.2010.

A new blend has been added to the “Terblend” N series – previously applied mainly as a material that allows the creation of matte surfaces without coating and that offers a favourable profile in terms of acoustics and feel. “Terblend” N BX 13043 is BASF’s first ASA/PA blend, in which ASA replaces ABS providing a material with high toughness, flowability and UV stability. BASF claims that the new blend is more chemical resistant than current “Terblend” N grades. In weathering tests that simulate exposure to sunlight at high temperatures for up to 1000 hours, the ASA/PA blend exhibited results that were comparable to UV-stabilised “Luran” S (ASA) and considerably better than conventional ABS/PA blends. In vehicle interior applications, the improved UV resistance is of special significance as light fastness makes this material even more attractive. In recreational equipment and gardening tools, toughness and sturdiness is most important. In all of these applications, the new material can be used uncoated, making it cost-effective.

A new blend has been added to the “Terblend” N series – previously applied mainly as a material that allows the creation of matte surfaces without coating and that offers a favourable profile in terms of acoustics and feel. “Terblend” N BX 13043 is BASF’s first ASA/PA blend, in which ASA replaces ABS providing a material with high toughness, flowability and UV stability. BASF claims that the new blend is more chemical resistant than current “Terblend” N grades. In weathering tests that simulate exposure to sunlight at high temperatures for up to 1000 hours, the ASA/PA blend exhibited results that were comparable to UV-stabilised “Luran” S (ASA) and considerably better than conventional ABS/PA blends. In vehicle interior applications, the improved UV resistance is of special significance as light fastness makes this material even more attractive. In recreational equipment and gardening tools, toughness and sturdiness is most important. In all of these applications, the new material can be used uncoated, making it cost-effective.

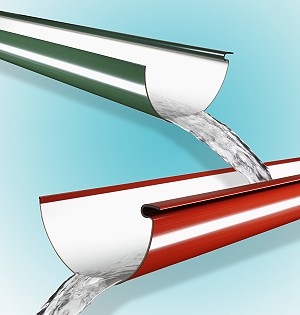

Luran S 767 KE not only flows more easily than its predecessors but it is also shinier. (Photo: BASF) |

The new “Terblend” N grades, NM-21 EF and NG-02 EF, provide enhanced flowability, allowing for more energy-efficient and cost-effective processing. The first can be processed easily through injection moulding and can be used for large and complex visible parts such as centre consoles in vehicle interiors or motorcycle fairings. The second, a glass fibre reinforced material, combines high flowability with mechanical strength leading to a material suitable for highly stressed, thin-walled parts.

“Terluran” HH (high heat) ABS is stiff, hard and impact-resistant and can operate at up to 112 °C while remaining dimensionally accurate and retaining its toughness and flowability. It is straightforward to process and parts can be easily coated or metallised.

“Terluran” HH 102 combines toughness and flowability with a high-gloss surface and a low level of blooming. High scratch- and abrasion resistance mean components made of “Terluran” HH 102 retain their appearance even after a long period of time in applications such as vacuum cleaners.

A new material has been added to BASF’s “Luran” S ASA range. Improved flowability and high finish are claimed for “Luran” S 767 KE, which can now be readily co-extruded with PVC, even at low melt temperatures, the company says. According to Marko Blinzler, who works in product development of styrene copolymer specialities at BASF: “It imparts co-extruded cover layers on PVC exterior applications with a surface that adheres well, is highly glossy and also withstands weathering much better than pure PVC. Together with the properties of the new grade, the well-known colour brilliance and durability of “Luran” S make this product suitable for applications such as colour-fast and high-gloss gutters that are easy to adapt to the design of the house.” “Luran” S 767 KE recently went into the serial production of “Plasa”, a gutter made by the Plastmo Polska (Raszyn / Poland; www.plastmo.pl).

BASF has also been carrying out testing on colour fastness and gloss retention of “Luran” S during outdoor use to identify new ways to improve and refine UV stabilisation. The company says a new approach has recently shown great optimisation potential with potential benefits in the automotive industry and the construction sector. New UV stabilised grades are currently undergoing laboratory testing in preparation for a market launch, the company said.

e-Service:

The chart-presentation given by Markok Blinzler at BASF´s pre-K press conference can be obtained on the following webpage as a PDF document

“Terluran” HH (high heat) ABS is stiff, hard and impact-resistant and can operate at up to 112 °C while remaining dimensionally accurate and retaining its toughness and flowability. It is straightforward to process and parts can be easily coated or metallised.

“Terluran” HH 102 combines toughness and flowability with a high-gloss surface and a low level of blooming. High scratch- and abrasion resistance mean components made of “Terluran” HH 102 retain their appearance even after a long period of time in applications such as vacuum cleaners.

A new material has been added to BASF’s “Luran” S ASA range. Improved flowability and high finish are claimed for “Luran” S 767 KE, which can now be readily co-extruded with PVC, even at low melt temperatures, the company says. According to Marko Blinzler, who works in product development of styrene copolymer specialities at BASF: “It imparts co-extruded cover layers on PVC exterior applications with a surface that adheres well, is highly glossy and also withstands weathering much better than pure PVC. Together with the properties of the new grade, the well-known colour brilliance and durability of “Luran” S make this product suitable for applications such as colour-fast and high-gloss gutters that are easy to adapt to the design of the house.” “Luran” S 767 KE recently went into the serial production of “Plasa”, a gutter made by the Plastmo Polska (Raszyn / Poland; www.plastmo.pl).

BASF has also been carrying out testing on colour fastness and gloss retention of “Luran” S during outdoor use to identify new ways to improve and refine UV stabilisation. The company says a new approach has recently shown great optimisation potential with potential benefits in the automotive industry and the construction sector. New UV stabilised grades are currently undergoing laboratory testing in preparation for a market launch, the company said.

e-Service:

The chart-presentation given by Markok Blinzler at BASF´s pre-K press conference can be obtained on the following webpage as a PDF document

26.07.2010 Plasteurope.com [216786]

Published on 26.07.2010